Aufgrund steigender Arbeitskosten in vielen internationalen Lieferketten, logistischer Engpässe, geopolitischer Risiken und zunehmendem Druck in Bezug auf Nachhaltigkeit reicht die alte Strategie der Beschaffung aus dem Land mit den niedrigsten Kosten einfach nicht mehr aus. Während die Beschaffung aus dem Land mit den niedrigsten Kosten wahrscheinlich kurzfristige Einsparungen ermöglichte, führte sie wahrscheinlich auch zu höheren Risiken in Bezug auf schlechte Qualität, Versorgungsunterbrechungen oder viele andere versteckte Kosten. Hier kommt der Begriff Best-Cost Country (BCC) Sourcing ins Spiel - eine durchdachtere und strategischere Art, über Gesamtkosten und -wert nachzudenken. Die Frage ändert sich nun von "Wie billig können wir sein?" zu "Welcher Standort hat den insgesamt besten Wert in Bezug auf Kosten, Fähigkeiten, Qualität, Zuverlässigkeit und Risiko dieser Kategorie?"

Was ist BCC Sourcing?

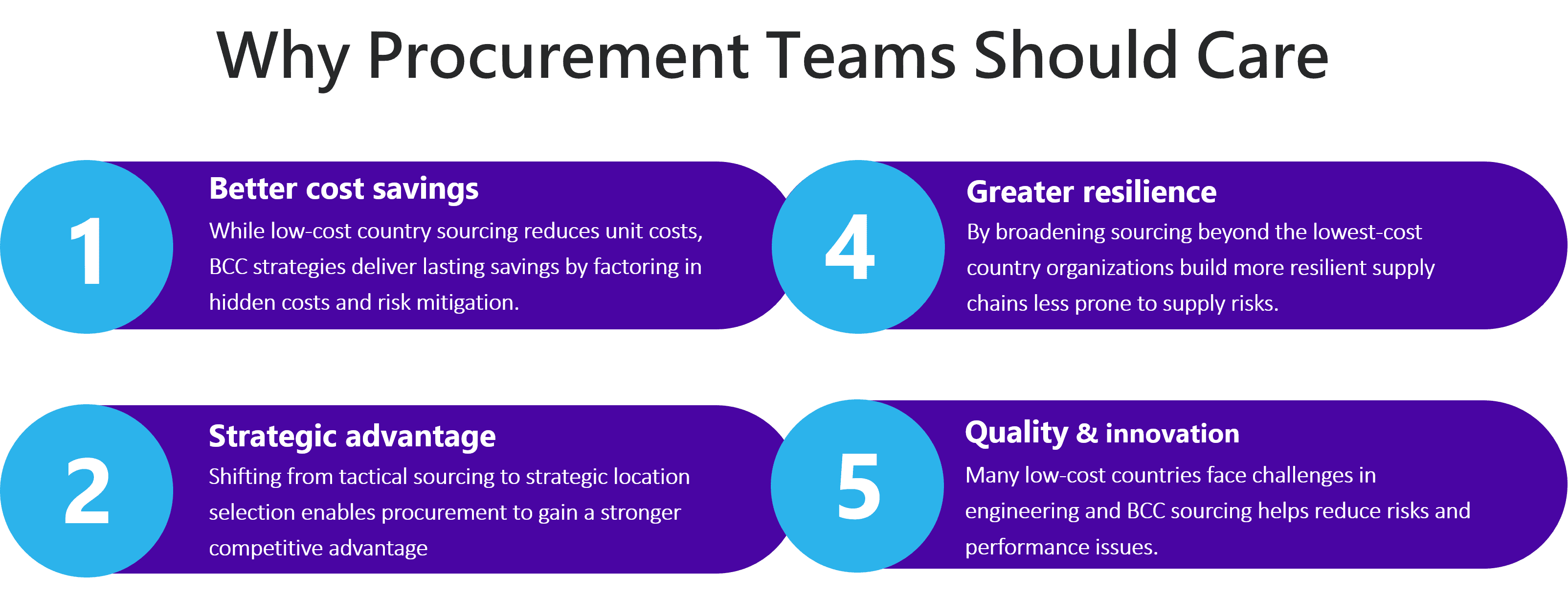

Best-Cost Country Sourcing bedeutet, Beschaffungsstandorte mit dem auszuwählen, was wir als das beste Gesamtleistungsversprechen bezeichnen, im Gegensatz zu den niedrigsten Kosten pro Einheit. Die wichtigsten Dimensionen sind:

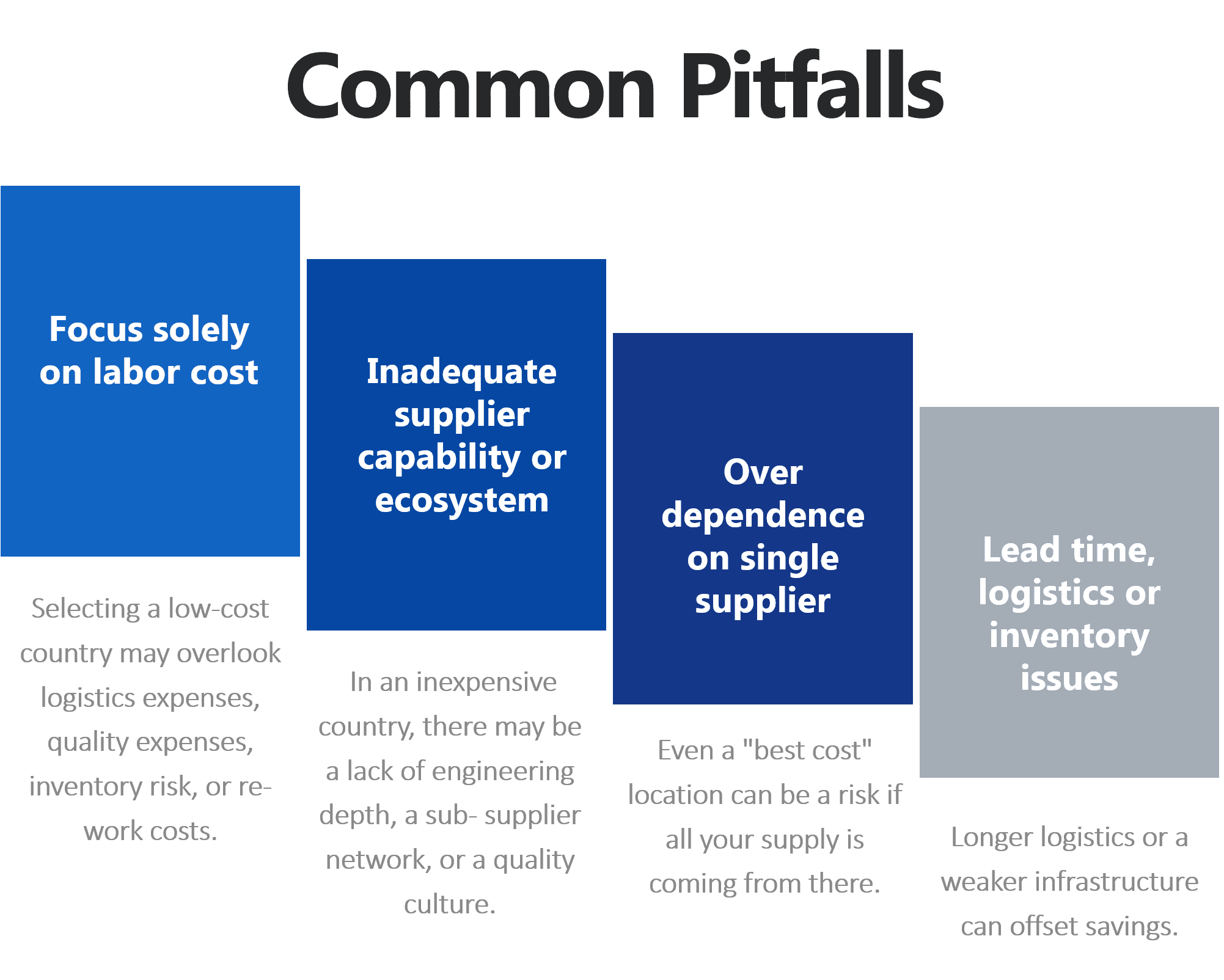

Gesamtbetriebskosten (TCO): Arbeitskosten, Materialkosten, Nebenkosten, Logistik, Zölle, Tarife, Kosten für die Lagerhaltung, Qualitätskosten, After-Sales-Kosten.

Lieferantenleistung: Qualitätskonsistenz, technische Fähigkeiten, Produktionsflexibilität, Vorlaufzeit, pünktliche Lieferung.

Länder-/Standortrisiko und -eignung: politische und regulatorische Stabilität, kulturelle Eignung, Infrastruktur, Währungs- und Handelsregime, Zuverlässigkeit der Logistik.

Strategische Ausrichtung: Passt der Beschaffungsstandort zu Ihrer Geschäftsstrategie (Innovation, Markteinführungsgeschwindigkeit, regionaler Zugang) und nicht nur zu Einsparungen?

Zusammenfassend lässt sich sagen: Beim BCC Sourcing geht es darum, Mehrwert zu schaffen und nicht nur Kosten zu sparen.

Hauptelemente einer BCC Sourcing Strategie

Definition der Kategorie- und Geschäftsanforderungen: Geben Sie für jede Ausgabenkategorie (Komponenten, Dienstleistungen, Rohstoffe) das Kostenziel, die Qualität, die Vorlaufzeit, die Innovation, geografische/regionale Beschränkungen, ESG/Nachhaltigkeit und den Bedarf an Lieferantenentwicklung an.

Verschiedene Kategorien benötigen möglicherweise unterschiedliche "Best-Cost"-Geografien.

Entwicklung eines Länderbewertungsrahmens: Berücksichtigen Sie Kostenüberlegungen (Arbeitskosten, Materialkosten, Nebenkosten), Logistik (Fracht, Häfen, Binnenland), Handel/Zölle/Abgaben, Währungsrisiko, Lagerkosten, Qualitäts-/Nacharbeitskosten.

Erstellung einer Auswahlliste von Lieferanten und Standorten: Katalogisierung der Lieferantenlandschaft in den Zielregionen: Anzahl der fähigen Lieferanten, Zertifizierungen, Reifegrad des Clusters, sekundäre Lieferanten, potenzielles Risiko von Einzelquellen. Durchführung von Werksaudits, Stichprobenprüfungen und Lieferantenfähigkeitsbewertungen.

Governance, Überwachung und kontinuierliche Überprüfung: Planen Sie beim Übergang von der bestehenden Beschaffung zu einem neuen BCC-Standort die schrittweise Einführung und Ausgliederung, verwalten Sie Lagerbestände, koordinieren Sie logistische Anpassungen und kommunizieren Sie mit den Beteiligten.

Relevanz für indische Beschaffungs- und Sourcing-Teams

Für Beschaffungsteams in Indien (oder solche, die aus/in Asien beziehen) hat BCC Sourcing einen spezifischen Kontext:

Indien selbst entwickelt sich für eine Reihe von Kategorien zu einem "Best-Cost"-Land: qualifizierte Arbeitskräfte, verbesserte Infrastrukturkosten, wettbewerbsfähige Kostenbasis, Englischkenntnisse.

Gleichzeitig kann die Beschaffung anderswo (Vietnam, Malaysia, Osteuropa usw.) je nach Kategorie eine praktikable "Best-Cost"-Option sein. Einige Unternehmen übernehmen beispielsweise das Sourcing-Modell "China + 1".

Für indische Unternehmen, die für globale Märkte beschaffen, kann BCC auch dazu beitragen, zu validieren, ob Indien die führende Option für eine bestimmte Kategorie ist oder ob sie eine diversifizierte Beschaffungsbasis haben sollten.

Logistik und Nähe (z. B. zu den Märkten des Nahen Ostens, Afrikas und des asiatisch-pazifischen Raums) können zusätzlich zu den Kosten in die "Best-Cost"-Entscheidung einfließen.

BCC Sourcing in der Praxis

Eine Erfolgsgeschichte: Ein globaler Hersteller in Westeuropa stand vor der Notwendigkeit, die Produktionskosten zu senken und seine Lieferanten zu diversifizieren. Sie initiierten eine BCC-Sourcing-Strategie, die Folgendes umfasste: Aufbau eines funktionsübergreifenden Projektteams, Erstellung einer Auswahlliste von Ländern, z. B. Indien, Türkei, Osteuropa für ihre endgültige Quelle, Qualifizierung neuer Lieferanten, Implementierung von digitalem Audit- und Risikomanagement, Transfer von Einkaufsvolumen im Wert von 130 Millionen Euro und Ausschöpfung von jährlichen Einsparungen in Höhe von etwa 28 Millionen Euro.

Dies deutete darauf hin, dass eine BCC-Strategie nicht nur Kosteneinsparungen demonstrierte, sondern auch die Widerstandsfähigkeit durch Diversifizierung der Lieferbasis über Hochkostenländer hinaus verbesserte.

Bei UnivDatos sind wir in einer starken Position, um Ihnen zu helfen, das Beste aus dem BCC Sourcing herauszuholen. Mit unseren robusten analytischen Fähigkeiten und globalen Sourcing-Informationen unterstützen wir Sie bei:

Finden optimaler Sourcing-Standorte und Benchmarking von Sourcing-Entscheidungen. Wir verwenden Kostendaten, Risikoanalysen auf Länderebene und die Reife des Lieferantenökosystems. Entwicklung eines Sourcing-Playbooks: kategoriespezifische Sourcing-Strategien, Shortlist von Lieferanten und Bewertung der Fähigkeiten sowie Risikominderung (Qualität, Logistik, Compliance). Umsetzung der Sourcing-Verlagerung mit starker Governance; Wir arbeiten durch einen schrittweisen Übergang, das Onboarding von Lieferanten, die Leistungsüberwachung und die kontinuierliche Optimierung, um die Widerstandsfähigkeit der Lieferkette und die Wertschöpfung aufzubauen.

Kontaktieren Sie unsere Analytics-Experten, um eine Beratung zu vereinbaren und entdecken Sie, wie wir Ihre Reise zu einer datengesteuerten Organisation beschleunigen können.