“Revolutionizing the Food and Beverage Industry: The Rise of Robotics and Automation”

Overview

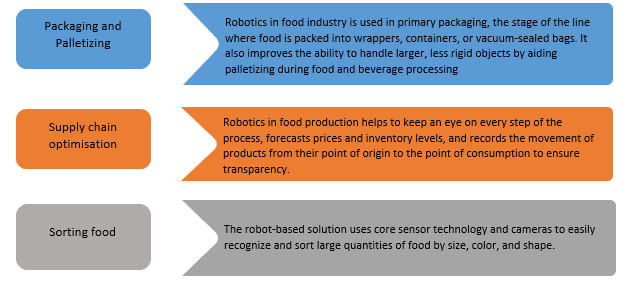

Technology plays a vital role in the food production and delivery process. Manufacturers are increasingly using robotics and data processing to simplify the food manufacturing process. Robotics can greatly improve packaging, improve shelf life and food safety. Robotics, machines, drones, and 3D printing have made food production simpler and more innovative.

Food and beverage manufacturers are using automation and robotics to address labour shortages and keep pace with growth and labour-intensive e-commerce. The food and beverage sector is evolving continually from production to delivery hence it is a complex process that must run smoothly to meet consumer demand.

Food and beverage manufacturers and grocers are finding new ways to increase sales, both online and offline. Robotics help alleviate some of the burden on workers and improve

efficiency across the food and beverage supply chain.

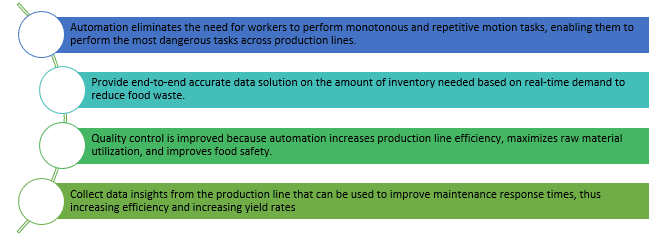

Benefits of Using Robotics in Food and Beverage Industry

Market Growth of Robotics in Food and Beverage Industry

The global food and beverage robot market was valued at $2,047.3 million in 2020 and is projected to reach $5,787.9 million by 2031, growing at a CAGR of 10.4% from 2022 to 2031. Various technological advances in many fields have made fictional robots a reality. The growing demand for increased productivity has led to an increase in the use of robots to automate tasks, making them an integral part of various industries.

Due to the rising population and for increased productivity in food processing, there is a considerable increase in the demand for food robots. The market for food robots is also anticipated to benefit from rising investments in automation in the food industry.

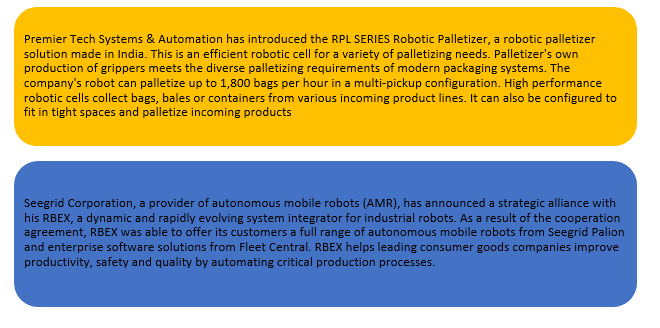

Recent Development of Robotics in Food and Beverage Industry

Recent and Future Trends of Robotics in Food and Beverage Industry

Dark Kitchen- The Dark Kitchen is part of an entirely new business model for food manufacturers, accelerated during the Covid-19 pandemic. The dark kitchen is optimized for delivery rather than for seated customers or traditional takeout. From packaging and palletizing to actual food preparation in fully automated dark kitchens, robots can be used everywhere.

COBOT Application- Cobots ease of programming allows food and beverage manufacturers to quickly adapt to new product and delivery requirements. Collaborative robotic arms can be reprogrammed, moved, and reused so even smaller facilities can run multiple lines or switch from production to packaging in the same footprint.

Cloud Based Inventory Tracking- Using smart sensors to track products reduces complexity and makes deliveries faster and more flexible. Short reaction times and reliable, accurate measurements allow to optimize processes and save energy, time, and effort.

Top of Form

Bottom of Form

Conclusion

The implementation of robotics in food manufacturing has many benefits, including less human error and waste of abundant produce, reduced storage/delivery and transportation costs, faster service, voice search, and more personalized one step forward to enable ordering. The use of robotics and AI in the F&B industry is becoming increasingly important, with companies working together to co-develop technologies that facilitate research, manufacturing, and distribution.

Over the next 20 years, many human activities involved in food processing, packaging and delivery will be fully automated. Robotics are used where it makes sense technically and economically. Complex tasks are automated and cobots work alongside humans. Robots are getting smarter and communicating with each other more effectively. Just as computers and mobile phones have become popular in recent years, robots have the potential to become omnipresent in the food industry and in our lives.

Author: Suryansh Verma