The Digital Transformation of the Food & Beverage Industry

- Himanshu Patni

- June 28, 2023

- BLOG, Chemical

- Digitalization in Food & Beverage Industry, Digitalization in Food & Beverage Industry Analysis, Digitalization in Food & Beverage Industry Growth, Digitalization in Food & Beverage Industry Outlook, Digitalization in Food & Beverage Industry Share, Digitalization in Food & Beverage Industry Size

- 0 Comments

Digitalization is digital transformation and the integration of digital technologies into all the aspects of a business, with the aim of improving efficiency and performance. Its use in the digital food & beverages industry is to enhance productivity, efficiency, customer experiences and food quality.

Digitization provides an opportunity to integrate operations working in isolation to systemize them to perform operations in a more efficient and productive manner. It allows to greatly enhance the capability of the facility to comply with the safety regulations.

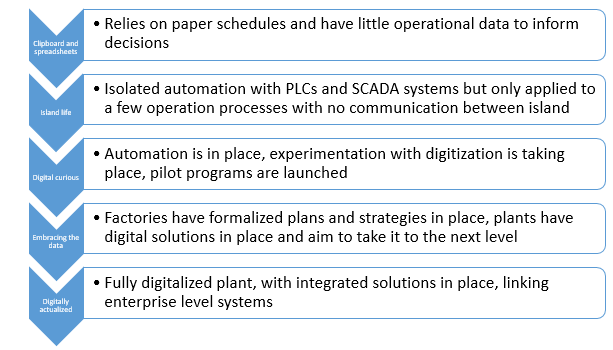

Five stages of the food & Beverage industry towards digitization

Examples of Digitalization in Food & Beverage Industry

Liferay– Digitization, which offers an open-source portal for enterprises, offers digital transformation that enables people to create a personalized view for users. From changing how your included apps and tools function to customizing the events calendar

Salesforce– It provides database management, providing to integrate sales functions end-to-end, be it communications to stakeholder management or details of sales cycles

Microsoft– It helps to track demand, manage inventory, and analyse insights related to process efficiency. It allows to streamline distribution through improved warehousing processes, real-time data updates and effective management of changing user demands

Challenges of Digitalization in Food & Beverage Industry

Challenges faced by the industry in the adoption of digitization technologies are the reliance on the suppliers to provide the technical resources to handle the integration process, ability to see the benefits of a given system and lack of dedicated staff with the required skills to implement the digitization project.

Application of Digitalization in Food & Beverage Industry

More Accurate and Immediate Data Collection– One of the core principles of digital transformation is to replace analog processes with modern and integrated technologies. In doing so, it immediately reduces or eliminates the inaccuracies, delays and lost data associated with manual processes. For example, ERP platforms designed for food & beverage companies can integrate with smart sensors, scales, meters, and thermometers

Safer Products and Procedures– High safety standards are set by the regulatory agencies for uncompromising safety standards and potentially hazardous safety standards

The right digital transformation strategy can help streamline pivots in times of transition and process automation to make up for employee’s unavailability

Greater Efficiency and Profitability– Good data has the ability to assist with better decision-making, which includes digital transformation technologies, analytics tools, or strategic planning functionalities. By looking at the efficiency and profitability results that a purpose-built ERP system can collect, allowing it to identify issues in the current processes. These platforms also make financial data easily accessible, informing decisions about which product lines to focus on

Better forecasting with AI– Food & Beverages needs to optimize their warehousing operations, as per the fluctuating demands, based on consumers’ needs and preferences

Companies can use AI to predict what their buyers might need. AI-powered software can create forecasts, track demand, and other supplies accordingly

Simplification of In-House tasks– Manufacturing ERP systems, can automate many administrative and operational tasks. This includes food safety and maintenance activities and some establishments have implemented online ordering systems, allowing them to bypass the third-party fees and delivery services

Plant Electrical Systems– The power supply impacts everything else in the plant and understanding the energy use is one of the easiest ways to identify opportunities for cost savings. Toward this end, smart circuit breakers and transformer monitoring can help

Conclusions

Digitization mainly involves 3 broad steps that can be summarized as sensing, referring to the ability to gather data. The next step is to make sense of gathered data by analysing the data, and finally leveraging the gained insights to implement actionable intelligence. Adoption of digital solutions along with the existing automation systems present in the factory, provides a tremendous ability to improve key performance indicators of the food & beverage industry, which include cost, quality, safety, and sustainability

Author: Abhishek Saini