Author: Vikas Kumar

15 May 2023

Flue Gas Desulfurization (FGD) is a process used to remove sulfur dioxide (SO2) from the flue gas emissions produced by power plants, industrial boilers, and other sources that burn fossil fuels. Sulfur dioxide is a major contributor to acid rain, and the FGD process is designed to reduce the amount of this harmful pollutant released into the atmosphere. FGD systems are effective at reducing sulfur dioxide emissions, but they also have some drawbacks. They can be expensive to install and maintain, and they can consume significant amounts of water and energy. Additionally, the solid waste products produced by FGD systems must be disposed of properly to prevent environmental contamination. FGD technology has been widely adopted in many countries to reduce SO2 emissions and improve air quality. However, the process also has some environmental drawbacks, such as the generation of large amounts of waste products and the consumption of large amounts of water and energy. Flue Gas Desulfurization (FGD) plays an important role in power generation as it helps to remove sulfur dioxide (SO2) from the exhaust gases produced by burning fossil fuels such as coal, oil, and natural gas.

Get the inside scoop with Sample report:- https://univdatos.com/report/flue-gas-desulfurization-fgd-market/get-a-free-sample-form.php?product_id=38130

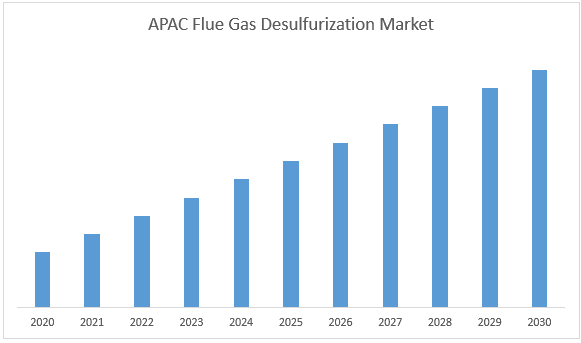

Further, the APAC Flue Gas Desulfurization (FGD) Market is expected to grow at a strong CAGR of 6.0% during the forecast period (2022-2028). The Flue Gas Desulfurization (FGD) market in the Asia Pacific region is expected to grow significantly in the coming years. This growth can be attributed to the increasing demand for electricity in the region, which has led to the construction of numerous coal-fired power plants. China is currently the largest market for FGD systems in the Asia Pacific region, due to its large number of coal-fired power plants and strict environmental regulations. India is also expected to experience significant growth in the FGD market, as the country continues to expand its energy infrastructure and implement more stringent emission standards. Other countries in the region, such as Japan, South Korea, and Southeast Asian nations, are also investing in FGD technology to comply with their respective environmental regulations and reduce air pollution. Moreover, several countries in Asia Pacific, such as China and India, have set ambitious targets to reduce emissions, and FGD systems are expected to play a key role in achieving these targets. The rising awareness of the harmful effects of air pollution on public health is also driving the demand for FGD systems.

FIG. 1 APAC Flue Gas Desulfurization (FGD) Market Revenue (2020-2028)- USD Mn

For a detailed analysis of the Global Flue Gas Desulfurization (FGD) Market browse through:-https://univdatos.com/report/flue-gas-desulfurization-fgd-market/

Based on type, the market is bifurcated into dry gas and wet gas system. The wet gas system is expected to register a significant market share in the market owing to its higher incorporation in power plants, industrial boilers and other sources. The wet FGD process typically involves three main stages: absorption, oxidation, and byproduct removal. During the absorption stage, the flue gas is mixed with a water-based slurry of limestone or lime, which absorbs the sulfur dioxide. In the oxidation stage, the calcium sulfite is oxidized to form calcium sulfate, which is then removed from the system. Finally, any byproducts produced during the process, such as gypsum, are removed and disposed of. Wet FGD is a widely used technology for controlling emissions of sulfur dioxide from power plants and other industrial facilities. It is highly effective, with removal efficiencies of up to 95% or more, and is also relatively low cost compared to other control technologies.

On the basis of end-users, the market is segmented into chemical & petrochemical, cement, power plant, metal processing & mining, and others. The power plant segment is expected to witness significant CAGR during the forecast period owing to the increasing demand due to the higher emission of flue gas in power generation along with the increasing demand of energy and power. In addition, Wet scrubbers are the most commonly used FGD technology in the power industry. They use a liquid (typically limestone slurry) to absorb the SO2 from the flue gas. The absorbed SO2 reacts with the liquid to form calcium sulfate (gypsum), which can be used in various industrial applications. Overall, FGD systems are an essential technology for the power industry to reduce its impact on the environment and public health. They help power plants comply with environmental regulations and reduce their emissions of harmful pollutants.

Global Flue Gas Desulfurization (FGD) Market Segmentation

Market Insight, by Type

Market Insights, by End-Users

Market Insight, by Region

Top Company Profiles

Get a call back