Author: Vikas Kumar

24 July 2024

Key Highlights of the Report:

According to a new report by Univdatos Market Insights, Single pair ethernet market, is expected to reach USD 14457 Mn in 2030 by growing at a CAGR of 32%. Single Pair Ethernet (SPE) is a technology that provides Ethernet transmission over a single pair of copper wires, while also transmitting power to connected devices via Power over Data Line (PoDL). Single Pair Ethernet (SPE) enables the transmission of ethernet via a single wire pair, ensuring a cost-effective and space-saving connection of sensors. Some Benefits of single pair ethernet 50% lighter and more compact than traditional Fieldbus cables, SPE saves space inside robots, walls and floors, while reducing power and temperature control requirements. Faster, easier and less expensive installation reduces new build costs, allowing devices, sensors and actuators to be easily integrated into the existing Ethernet environment without additional interfaces. Standards-based connectivity with interchangeable plug-in M8 and M12 connector interfaces meets established requirements

Unlock Insights into the Single Pair Ethernet Market –https://univdatos.com/get-a-free-sample-form-php/?product_id=7482

The report suggests that the industrial demand for industrial automation is a significant driver of the single pair Ethernet (SPE) market, with profound impacts on efficiency, productivity, and operational flexibility. In industrial settings, automation plays a crucial role in streamlining processes, reducing labor costs, and improving overall production throughput. SPE meets the specific networking requirements of industrial automation by providing reliable and high-speed communication between various components such as sensors, actuators, controllers, and machinery. This enables seamless integration of automated systems, real-time monitoring, and precise control of manufacturing processes. Additionally, SPE’s ability to deliver power and data over a single cable (PoDL) simplifies installation, reduces cable clutter, and minimizes maintenance efforts, further enhancing the efficiency of industrial automation systems. Moreover, SPE’s ruggedized design and resistance to interference make it well-suited for deployment in harsh industrial environments, ensuring uninterrupted operation and minimizing downtime. Overall, the adoption of SPE in industrial automation leads to improved operational efficiency, increased production uptime, and enhanced competitiveness for industrial enterprises.

Apart from this, growing technological Power over Data Lines (PoDL), Time-Sensitive Networking (TSN), and Ethernet-APL driving innovation. These advancements are fueling the adoption of SPE across various industries for efficient and scalable networking solutions. Some of the recent strategic alliances are:

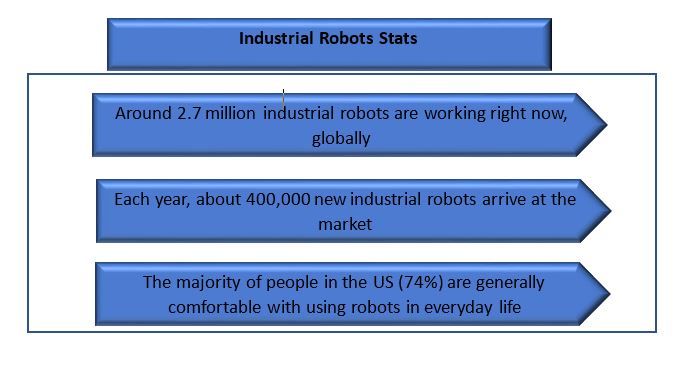

Industrial Robots Sector Gaining Maximum Traction in Market

In the segmentation of the single pair Ethernet (SPE) market within the realm of industrial robots, various factors shape the landscape of adoption and implementation. Industrial robots, integral components of modern manufacturing and automation processes, require reliable and high-speed communication networks to operate efficiently. SPE addresses these requirements by offering a robust and scalable networking solution tailored to the needs of industrial environments. Within the industrial robot segment, SPE finds application in several key areas. Firstly, it enables seamless communication between robot controllers and peripheral devices such as sensors, actuators, and vision systems, facilitating real-time data exchange and precise control. Secondly, SPE supports the integration of collaborative robots (cobots) into production lines, allowing for safe and efficient human-robot interaction through advanced sensing and communication capabilities. Additionally, SPE enables the implementation of predictive maintenance and condition monitoring systems in industrial robots, leveraging its ability to transmit large volumes of data reliably over long distances. Moreover, SPE contributes to the deployment of flexible and reconfigurable manufacturing systems by providing a standardized communication protocol that simplifies network architecture and reduces installation costs. Overall, within the industrial robot segment, SPE serves as a foundational technology driving innovation, efficiency, and scalability in modern manufacturing processes.

Conclusion

The single pair Ethernet (SPE) market is undergoing a significant transformation driven by technological advancements such as Power over Data Lines (PoDL), Time-Sensitive Networking (TSN), and Ethernet-APL. These innovations are revolutionizing networking solutions by providing efficient data transmission, power delivery, and real-time communication capabilities over a single cable. The integration of PoDL reduces infrastructure costs and simplifies installations in various industries, while TSN ensures precise data delivery critical for mission-critical applications. Ethernet-APL extends Ethernet to the field level in process automation, enhancing robustness and reliability in harsh environments. Moreover, the scalability, cost-effectiveness, and interoperability of SPE make it an attractive solution for modern networking requirements. The emergence of SPE standards and industry alliances further ensure compatibility and interoperability among different vendors, driving the adoption of SPE in various verticals including manufacturing, transportation, energy, and healthcare. With the increasing focus on digitalization, Industry 4.0, and IoT deployments, as well as sustainability and energy efficiency, the demand for SPE is expected to grow, positioning it as a future-proof platform for next-generation networks.

Get a call back