- Home

- About Us

- Industry

- Services

- Reading

- Contact Us

Stringent governmental initiative has increased the overall demand for more fuel economic ground transportation vehicles is expected to drive the demand for Lightweight material in automotive sector!

Author: Vikas Kumar

December 30, 2021

Automotive Lightweight Material is expected to witness CAGR growth of more than 7.3% during the forecast period 2021-2027. Stringent governmental initiative has increased the overall demand for more fuel economic ground transportation vehicles, this has led to the entry of new materials such as new high-strength steels, polymer composites, aluminum alloys, and magnesium among other lightweight material for vehicle manufacturing. To cater to the growing demand for emission reductions and increased fuel economy across all new generation vehicle, the steel industry has accelerated the implementation of new innovative steels over other emerging lightweight materials.

For a detailed analysis of the market drivers browse through https://univdatos.com/report/automotive-lightweight-material-market/

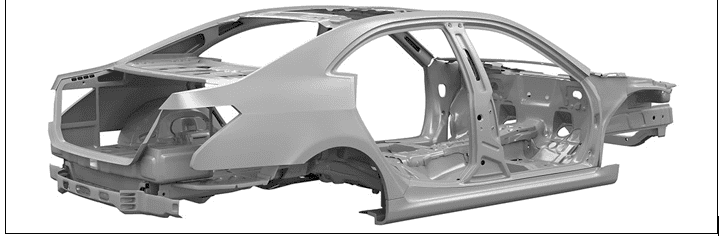

The introduction of lightweight materials has revolutionized the way we travel, be it in planes, trains, and automobiles, to space flight, to heavy machinery and shipping, the transportation industry is witnessing a change towards a lightweight future. Lightweight material offers several benefits but not limited to including increased speed, range, and fuel economy, among others. The innovation of lightweight material has led to a better understanding of safety in the automotive industry. To cater to the growing demand for lightweight material in the automotive sector, steel manufacturers are engaged in development of novel high strength steels for automotive sector also, highlight its benefits compared to aluminum alloys. Global steel industry in response to the lightweight material launched Ultra-Light Steel Auto Body, Advanced Vehicle Concepts (ULSAB-AVC) project in 1995 with an aim to reduce the overall mass of the vehicle by 25%.

For a detailed analysis of the Covid-19 Impact on the market browse through https://univdatos.com/get-a-free-sample-form-php/?product_id=12983

Based on Material Type, the Automotive Lightweight Material Market is segmented into Metal, Plastics, Composites, Elastomer. Composite segment is expected to witness significant growth during the forecast period. As per one of the top consulting firms, since 2010, aluminum uses in the automotive sector have increased from 154 Kg per vehicle to 208 Kg per vehicle in 2020. It is further expected to increase to 233 Kg per vehicle by 2026, an increase of almost 12% compared to 2020 level. Based on Component, the Automotive Lightweight Material Market is bifurcated into Frame, Powertrain, Interior Components, Exterior Components. Use of aluminum as lightweight material in the vehicle production is majorly limited to engine transmission, wheel heat exchangers, chassis, and suspension. High-cost act as main barrier for the use of aluminum in other vehicle parts.

For a detailed analysis of the market segments browse throughhttps://univdatos.com/get-a-free-sample-form-php/?product_id=12983

Based on Application, the Automotive Lightweight Material Market is bifurcated into Body in White, Chassis and Suspension, Powertrain, Closures, Interiors, Others. New and innovative product developments and compositions are gained popularity in the automotive lightweight material market. For instance, in 2020, ESE Carbon Co., composites manufacturer in US, launched carbon fiber wheel which is made with customized fiber positioning and custom presses to reduce waste and increase scalability. Based on Vehicle Type, the Automotive Lightweight Material Market is bifurcated into Passenger Vehicles, Light Commercial Vehicles, Heavy Commercial Vehicles. Passenger Vehicle segment is expected to witness significant growth during the forecast period. Main application of aluminum in electric vehicle is aluminum sheet battery enclosure which can extend the driving range of the vehicle and allow vehicle to travel 10% more on a single charge.

For a better understanding of the market, the report is analyzed based on different regions including North America (US, Canada, Rest of North America); Europe (Germany, UK, France, Italy, Rest of Europe); Asia-Pacific (China, Japan, India, South Korea, Rest of Asia-Pacific); and Rest of World. Europe is expected to be the largest automotive lightweight material market during the forecast period. However, automotive lightweight material market is expected to witness significant growth in the Asia-Pacific owing to growing number of vehicle production and growing demand for luxury/premium cars owing to increased disposable income. Some of the major players operating in the market include BASF SE, ArcelorMittal, Toray Industries, Inc., Stratasys Ltd., Covestro AG, Alcoa Corporation, Owens Corning, Lyondellbasell Industries Holdings B.V., ThyssenKrupp AG, Tata Steel etc.

Request for Sample of the report browse throughhttps://univdatos.com/get-a-free-sample-form-php/?product_id=12983

Automotive Lightweight Material MarketSegmentation

Market Insight, by Material Type

- Metal

- Plastics

- Composites

- Elastomer

Market Insight, by Component

- Frame

- Powertrain

- Interior Components

- Exterior Components

Market Insight, by Application

- Body in White

- Chassis and Suspension

- Powertrain

- Closures

- Interiors

- Others

Market Insight, by Vehicle Type

- Passenger Vehicles

- Light Commercial Vehicles

- Heavy Commercial Vehicles

Market Insight, by Region

- North America

- US

- Canada

- Rest of North America

- Europe

- Germany

- UK

- France

- Italy

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Rest of World

Top Company Profiles

- BASF SE

- ArcelorMittal

- Toray Industries, Inc.

- Stratasys Ltd.

- Covestro AG

- Alcoa Corporation

- Owens Corning

- Lyondellbasell Industries Holdings B.V.

- ThyssenKrupp AG

- Tata Steel

Get a Callback

Related News

Subscribe to our newsletters

By submitting this form, I understand that my data will be processed by Univdatos as indicated above and described in the Privacy Policy. *