- Home

- About Us

- Industry

- Services

- Reading

- Contact Us

Need for increased efficiency and labor savings in poultry farming operations Across the Region have Propelled the Growth of the poultry keeping machinery Market in North America!

Author: Vikas Kumar

December 23, 2023

As the demand for poultry products continues to rise, farmers are seeking ways to streamline their operations and maximize productivity. Poultry keeping machinery offers solutions to achieve these goals. For instance, automated egg collection systems have become increasingly popular in large-scale poultry farms. These systems use mechanical arms or conveyor belts to collect eggs from the laying hens’ nests automatically. This eliminates the need for manual egg gathering, which can be time-consuming and physically demanding. By automating this process, farmers can save significant amounts of labor and reduce the risk of breakage or damage to the eggs. Another example is the use of automatic feeding systems in poultry farms. These systems are equipped with sensors that detect the birds’ feeding patterns and dispense the appropriate amount of feed at the right time. By eliminating the need for manual feeding, farmers can ensure a consistent and controlled feeding regime, which is crucial for the growth and health of the poultry.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=43170

This automation also allows farmers to allocate their time and resources more efficiently to other essential tasks. In addition, advancements in technology have led to the development of sophisticated climate control systems for poultry houses. These systems can monitor and regulate temperature, humidity, and ventilation, creating optimal environmental conditions for the birds. By maintaining a comfortable and stable environment, poultry-keeping machinery can enhance bird health, reduce stress, and improve overall productivity. Furthermore, waste management is a significant concern in poultry farming. Poultry-keeping machinery offers solutions to efficiently handle and dispose of manure and other waste materials. For example, automated manure removal systems can collect and transport waste from poultry houses to designated storage areas or composting facilities. This not only reduces manual labor but also helps maintain a clean and hygienic environment, minimizing the risk of disease transmission. Overall, the need for increased efficiency and labor savings in poultry farming has been a driving force behind the growth of poultry-keeping machinery. Through automation and advanced technologies, these machines provide farmers with practical solutions to optimize various aspects of their operations, from egg collection and feeding to climate control and waste management. By embracing these technological advancements, farmers can meet the growing demand for poultry products effectively while improving profitability and sustainability in the industry.

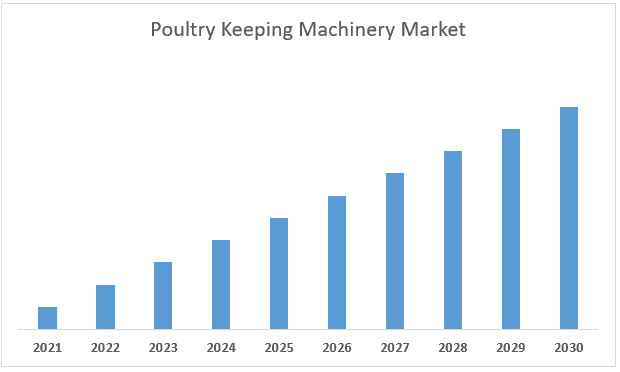

Further, the North America Poultry Keeping Machinery Market is expected to grow at a strong CAGR of xx% during the forecast period (2022-2030). Changing consumer preferences are also driving the growth of poultry-keeping machinery in North America. Many consumers are looking for more sustainable and ethically produced poultry products, and the use of automated machinery can help meet these demands. For example, some companies are now using robotics to produce “cage-free” eggs, which are produced without the use of cages and are seen as more humane by some consumers.

APAC Poultry Keeping Machinery Market Revenue (2021-2030)- USD Mn.

Based on the product type, the market has been categorized into Feeding, Watering, nesting, ventilation, climate control, broiler harvesting and slaughtering, and others. Among them, the broiler harvesting and slaughtering segment is expected to attain largest share of the market due to the increasing focus on sustainable and efficient production practices in the poultry industry. There is a growing awareness of the environmental impact associated with livestock production, including broiler farming. As a result, there is a need to optimize resource utilization, minimize waste generation, and reduce the carbon footprint of the entire production process. For instance, TIBOT Technologies, a France-based technology company, launched T-MOOV robotic technology in agriculture and poultry farming to reduce time consumed on repetitive tasks and maintain cleanliness on poultry farms.

Based on the Application, the market has been categorized as feeding chicken, feeding duck, feeding turkeys and others. Among them, the feeding chicken has a high market share as the nutritional requirements of chickens play a crucial role. Poultry farmers aim to provide balanced and adequate diets to ensure optimal growth, development, and overall health of the chickens. These diets typically consist of proteins, carbohydrates, fats, vitamins, and minerals, which are carefully formulated to meet the specific needs of the chickens at different stages of their life cycle.

For a detailed analysis of the Global Poultry Keeping Machinery Market browse through – https://univdatos.com/report/poultry-keeping-machinery-market/

Global Poultry Keeping Machinery Market Segmentation

Market Insight, by Product Type

- Feeding

- Watering

- Nesting

- Ventilation

- Climate Control

- Broiler Harvesting and Slaughtering

- Others

Market Insights, by Application

o Feeding Chicken

o Feeding Ducko Feeding Turkeyso OthersMarket Insight, by End-userso Farmo Poultry Factory

Market Insight, by Region

- North America

- U.S.

- Canada

- Rest of North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- Rest of APAC

- Rest of the World

Top Company Profiles

- Valco Industries, Inc

- Vencomatic Group

- TEXHA

- Petersime

- HAMEX-GmbH

- Big Dutchman

- Jansen Poultry Equipment

- Ziggity Systems, Inc

- AP Poultry Equipments

- TECNO POULTRY EQUIPMENT Spa

Get a Callback

Related News

Subscribe to our newsletters

By submitting this form, I understand that my data will be processed by Univdatos as indicated above and described in the Privacy Policy. *