“Offsite Construction: Revolutionizing Building Processes for Speed and Efficiency”

Offsite Construction

Offsite construction refers to the fabrication, planning, design, fabrication, and assembly of building components at a location other than their final installation site to support a fixed structure’s rapid speeds and construction efficiency.

Such building elements may be prefabricated offsite at another site and transported to the site, or at the construction site and then transported to their final location.

Different forms through which offsite construction can be performed

- Volumetric Construction: In volumetric construction, three-dimensional units are manufactured in the factory, then brought to the site and bolted together. Construction frames can be made of steel, wood, or concrete. The factory has a production quality control system under the approval of a third party

- Hybrid Construction: Hybrid construction combines both volumetric and penal methods to develop a single building. That is why this construction is also called semi-volumetric. Hybrid systems are fully fabricated or factory-fabricated building installations

- Penalized Construction: These are flat panel units used as walls, floors, or roof panels to create a complete structural shell. These panel units are factory-fabricated and shipped to the site for assembly into a three-dimensional structure or for mounting into an already-built structure on site

- Sub-Assemblies and Accessories System: Sub-assembly is the process by which building components are initially constructed on site before being permanently erected on site. These include construction elements, materials, equipment, and prefabricated parts. This construction type involves the manufacture of small building components like roof trusses, floors piping, staircases, roof trusses, precast concrete beams, and columns

Characteristics of Offsite Construction

The off-site building construction uses a variety of materials, scales, and systems, as well as cutting-edge production techniques, digital software, and contemporary assembling methods.

The following circumstances make off-site construction most suitable:

Benefits of the Offsite Construction

- Faster project completion and increased productivity: Prefabrication and modular construction allow for the off-site construction of components while site work is being done, which speeds up project completion and boosts efficiency. External factors like weather are less likely to affect the timetable when components are prefabricated, tested, and inspected before they arrive at the job site. Additionally, onsite setup and pre-assembly time are decreased. According to estimations, off-site building projects are completed 20% to 50% more quickly than conventional construction projects

- Cost management and predictability: In addition to the cost savings that result from finishing projects more quickly, the components themselves may result in savings since it may be more cost-effective to create at the factory than on the job site. With fewer external constraints – weather, cost of materials/labour on-site versus off-site construction, storage expenses, and more – affecting project costs

- Predictability of quality and process: Predictable results are produced through automated pre-assembly, which demands adherence to repeatable procedures. Reducing on-site construction minimizes the possibility of product quality variation. Before shipping, components made off-site must pass quality control

- Increased worker safety: Off-site construction decreases the time workers spend in the field, a less controlled setting than a factory in terms of preserving social distance, and increasing worker safety

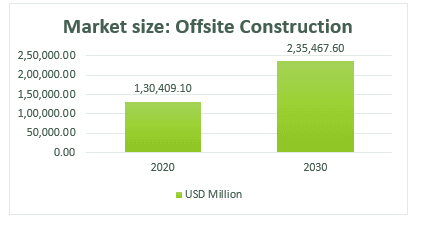

Market size: Offsite Construction

The off-site construction market is projected to reach $235,467.6 million by 2030 from $130,409.1 million in 2020, with a CAGR of 5.9% from 2021 to 2030.

Off-site construction is ideal for applications such as mobile offices, cafes, RVs, power plants, and restrooms. Off-site structures are made of steel, wood, concrete, and many other materials. The use of galvanized steel for its rigidity, strength, and durability is driving the growth of the off-site construction market.

Growth drivers: Offsite Construction

Conclusion

Offsite construction refers to the manufacturing, planning, design, fabrication, and assembly of building elements at a location other than their final installed location to support the rapid speed of, and efficient construction of a permanent structure. Such building elements may be prefabricated offsite in a different location and transported to the site or prefabricated on the construction site and then transported to their final location. The output from an off-site construction has elements that are componentized, penalized, and modularized which are used to perform as structural elements, enclosure and service elements, or interior partition systems.

Author: Dipanshi Singh