Zamykanie Pętli: Badanie Modelu Obiegu Zamkniętego Łańcucha Dostaw dla Zrównoważonych Operacji

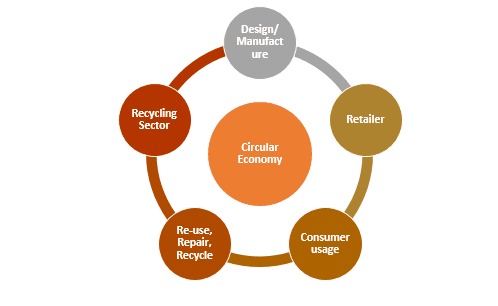

Aobiegowy łańcuch dostawwykorzystuje zasoby tak długo, jak to możliwe. Minimalizuje odpady na każdym etapie, w tym projektowanie, dystrybucję i dalej. Ramy obiegowego modelu biznesowego mogą być wykorzystane do stworzenia zrównoważonej strategii biznesowej. Te zrównoważone strategie biznesowe wyrażone są jako 3R w obiegowych modelach biznesowych: Redukuj, Ponownie wykorzystuj, Recyklinguj. Zatem, projektowanie i zarządzanie siecią przedsiębiorstw i użytkowników końcowych, które ma na celu minimalizację, utrzymanie i odzyskiwanie zasobów w celu osiągnięcia korzyści ekonomicznych, środowiskowych i społecznych, jest znane jako obiegowy łańcuch dostaw. Celem jest przekształcenie łańcucha dostaw z modelu liniowego (weź-zrób-wyrzuć) na obiegowy (bez odpadów), wspierając gospodarkę obiegu zamkniętego, która koncentruje się na zrównoważonym rozwoju i redukcji odpadów.

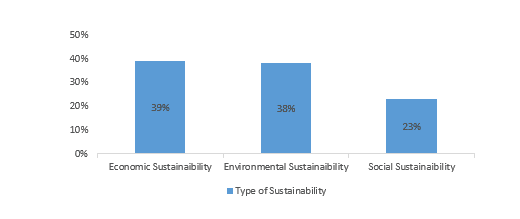

Przewidywano, że względy środowiskowe i ekonomiczne rozwiązania biznesowe miały najwyższy priorytet na podstawie tego wykresu. Ponowne używanie, recykling i wykorzystanie mniejszej ilości materiałów, komponentów i produktów to wszystko sposoby, w jakie czynniki ekonomiczne mogą obniżyć koszty dla klientów i biznesu. Czynniki społeczne obejmują dzielenie się zasobami i ponowne wykorzystanie wśród członków społeczności, w szczególności między przedsiębiorstwami, co poprawia interakcje. Efekty środowiskowe redukują wytwarzanie odpadów i zużycie zasobów.

Jak Kwestionować Stare Modele?

Zazwyczaj wytwarza system, który kosztuje dużo pieniędzy i zużywa zasoby naturalne. Na przykład górnictwo złota i węgla może uszkodzić ekosystemy i zakłócić funkcjonowanie pobliskich społeczności. Konwersja rudy na stal wymaga dużej ilości energii, co uwalnia dwutlenek węgla, który ociepla planetę. Model liniowy wytwarza odpady materiałowe jako produkt uboczny, który zajmuje miejsce i może zawierać zanieczyszczenia. Odpady trafiają w niepożądane miejsca. Tak zwana Wielka Pacyficzna Plama Śmieci jest tylko najbardziej znanym przykładem powszechnego zanieczyszczenia środowiska przez tworzywa sztuczne. Jednak produkty takie jak stal i plastik można poddać recyklingowi, naprawie i ponownemu wykorzystaniu w celu uzyskania potencjalnych korzyści. Ważnym czynnikiem jest w pełni obiegowa gospodarka bez odpadów i bez żadnych nowych materiałów.

To są następujące czynniki łańcucha dostaw, które są potrzebne w modelu obiegowym:

CzynnikiObiegowy Łańcuch Dostaw:

Konsumenci wyróżniają się jako jeden z głównych czynników napędzających obiegowy łańcuch dostaw w wielu przypadkach. Jednak większość łańcuchów dostaw w dużej mierze zależy od regulacji rządowych w ich wysiłkach zmierzających do stania się obiegowymi łańcuchami dostaw.

Rządy nakładają ograniczenia w wielu kwestiach w tym zakresie. Określają, które towary mogą być składowane na wysypiskach, które towary muszą być poddane recyklingowi i które łańcuchy dostaw muszą stosować jakie techniki, odchodząc od konwencjonalnych procedur. Aby poprawić przepływ produktów przy niższych kosztach, łańcuchy dostaw musiały przemyśleć sposób współpracy. W konsekwencji firmy logistyczne stron trzecich pojawiły się, aby zaspokoić popyt i usunąć ryzyko nadmiernych przewag konkurencyjnych w liniowym łańcuchu dostaw. W rezultacie, stary koncept recyklingu otrzymał nowe życie jako praktyczny i istotny element w sektorze logistycznym.

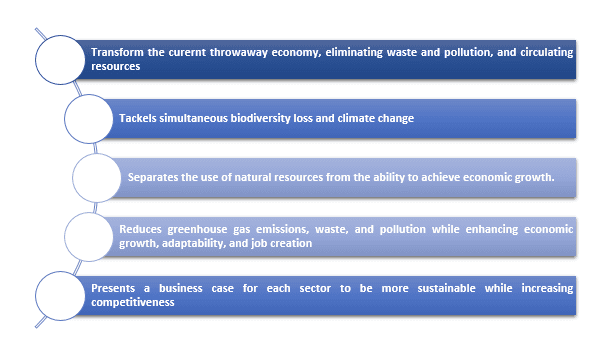

Korzyści płynące z obiegowego modelu biznesowego:

Wniosek:

Zamiast produkować przedmiot i wracać do początku łańcucha z zupełnie nowymi materiałami, obiegowe łańcuchy dostaw przetwarzają niewykorzystane fragmenty z powrotem do swoich łańcuchów wartości. Podsumowując, obiegowe łańcuchy dostaw wspierają środowisko o zerowej ilości odpadów. Firmy mogą budować infrastrukturę i łańcuchy dostaw, które wspierają skuteczną logistykę zwrotną. Przejrzystość, widoczność, innowacje i efektywność to jedyne wymagania dla firm i łańcuchów dostaw, aby przejść do gospodarki o obiegu zamkniętym. Z tego powodu powodowane są mniejsze szkody dla środowiska i wszyscy możemy przyczynić się do tworzenia zrównoważonej przyszłości i czystszej planety.

Autor: Sakshi Gupta