The Increasing Demand for Heavy-Duty Equipment has Propelled the Growth of the Slewing Bearing Market in the APAC Region!

Author: Himanshu Patni

12 August 2023

The increasing demand for heavy-duty equipment is boosting the Asia Pacific market in several ways. Heavy-duty equipment such as cranes, mining equipment, and construction machinery require slewing bearings to support their weight and movement. The growing construction and infrastructure industry in the region, as well as the increasing demand for minerals and metals, are driving the demand for heavy-duty equipment.

In addition, the increasing urbanization and industrialization in the region are also contributing to the demand for heavy-duty equipment. As more buildings and infrastructure are built, there is a greater need for cranes, excavators, and other heavy-duty equipment that require slewing bearings.

Access sample report (including graphs, charts, and figures):https://univdatos.com/report/slewing-bearing-market/get-a-free-sample-form.php?product_id=44442

Furthermore, the increasing demand for renewable energy sources in the region is also driving the demand for slewing bearings. Wind turbines, for example, require slewing bearings to rotate the blades and track the direction of the wind. As the region continues to invest in renewable energy, the demand for slewing bearings used in wind turbines is expected to increase.

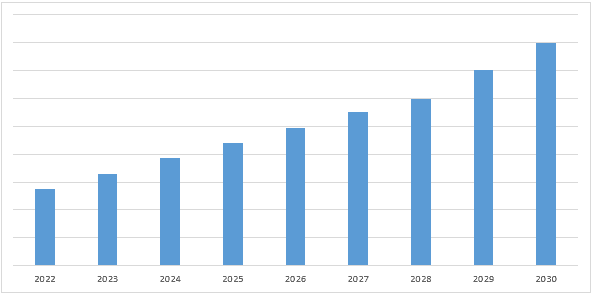

Further, the APAC Slewing Bearing Market is expected to grow at a strong CAGR of 28.0% during the forecast period (2022-2030S). APAC is anticipated to emerge as the fastest-growing slewing bearing market primarily owing to the spur in demand for heavy-duty equipment in China, India, and Japan. Meanwhile, China constitutes to be the largest market in the APAC region, accredited to rising expenditure on infrastructure.

- FIG. 1 APAC Slewing Bearing Market Revenue (2020-2030)- USD Mn

For a detailed analysis of the Global Slewing Bearing Market browse through – https://univdatos.com/report/slewing-bearing-market/

Based on product, the market is segmented into internal tooth, external tooth, and without tooth. Amongst these, the internal tooth segment dominated the market in 2021. This is because Internal tooth bearings have a more complex internal geometry, which allows for smooth and efficient rotation due to the teeth engaging with each other in a way that reduces friction and increases the load-carrying capacity of the bearing.

By design, the market is segmented into cross roller slewing ring bearing, bi-angular roller or taper,single-row four point contact ball slewing ring bearing, four- and eight-point contact ball, three-row roller slewing ring bearings, double-row ball slewing ring bearings, and others. Among these, double-row ball slewing ring bearings have a dominating share in the market. This is because they offer a high load-carrying capacity, high precision, and a high degree of stability. They are widely used in heavy-duty applications such as cranes, tower cranes, and large mining equipment. They also have a longer service life and are more cost-effective compared to other types of slewing bearings.

Global Slewing Bearing Market Segmentation

Market Insight, by Type

- Internal Tooth

- External Tooth

- Without Tooth

Market Insights, by Design

- Cross Roller Slewing Ring Bearing

- Bi-angular roller or Taper

- Single-row Four Point Contact Ball Slewing Ring Bearing

- Four- and Eight-point Contact Ball

- Three-row Roller Slewing Ring Bearings

- Double-row Ball Slewing Ring Bearings

- Others

Market Insights, by Application

- Radar

- Mining

- Construction

- Wind Turbines

- Onshore

- Offshore

- Others

Market Insight, by Region

- North America

- U.S.

- Canada

- Rest of North America

- Europe

- Germany

- UK

- Italy

- France

- Rest of Europe

- APAC

- China

- Japan

- India

- Rest of APAC

- Rest of the World

Top Company Profiles

- Fortigal Group S.p.a

- Schaeffler Group

- NTN Corporation

- Timken Company

- Rotis

- SKF

- IMO Group

- ThyssenKrupp Group

- Kinematics Manufacturing Inc.

- NSK Ltd.

Get a call back