Unleashing Efficiency and Automation: The Era of Smart Warehouses

The pinnacle of warehouse automation is a smart warehouse (in other words, automating various components of your warehousing operations). A smart warehouse is equipped with a number of automated and networked technology, similar to smart houses. Together, these technologies improve the warehouse’s production and efficiency while reducing the amount of human workers and their faults.

According to Royce Digital, “In manual warehouses, we typically saw personnel going around with lists, picking things, placing them into carts, and then transporting them to the shipping docks,” whereas “Orders are received automatically, after which the system validates if the products are in stock.” The requested items are subsequently put into containers by robot carts, which are then sent to the workers for pickup, using the pick-up lists.

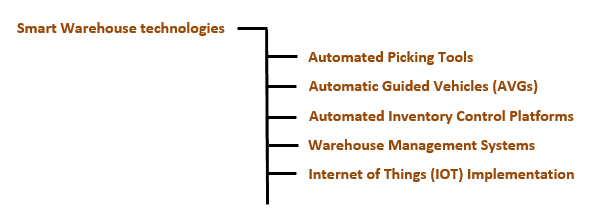

Popular Smart Warehouse Technologies

Automated Picking Tools

Now, when picking automation components are integrated into the flow, warehouses can profit from picking rates that are almost flawless. Pick-to-light, robotic order picking, and voice-controlled order picking are just a few of the tools that can be utilized to improve picking processes. For the quickest, most accurate automated reporting experiences, these technologies additionally make use of cutting-edge barcoding solutions that easily interact with your selected management software.

Automatic Guided Vehicles (AGVs)

AGVs, also known as automatic guided vehicles, are the best approach to speed up your storage and retrieval procedures in your warehouse. AGVs’ structural integrity is changing as technology advances, but even the types that have been around for a while have shown to be safer and produce a quicker return on investment than manual labor. Storage of pallets, racks, and other containers, as well as controls and automation of the entire receiving process, are some of their most crucial roles.

Automated Inventory Control Platforms

Automated inventory management systems are used in conjunction with a few other technical cornerstones, such as asset and inventory tags, to eliminate labor, guesswork, and unnecessary time from conventional inventory control.

Warehouse Management Systems

WMSs, sometimes referred to as warehouse management systems, are comprehensive software programmes that gather all of your crucial data onto one platform so that it can be conveniently accessed by internal players as well as any chosen supply chain participants.

Internet of Things (IoT) Implementation

The Internet of Things, or IoT, is more of a general idea than a specific technology, although it is frequently implemented in the most efficient smart warehouses in the world. IoT may optimize all of your operations so that their data resides in one, simple-to-access network when it is used to control a large number of moving parts, both automatic and manual. Through faster fulfilment rates, this improves a warehouse’s inventory control processes, labor planning, and, of course, its overall customer experience.

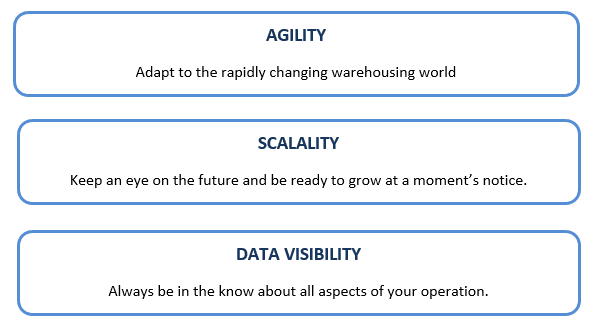

Key Features

Key Benefits

Examples of Companies with Smart Warehouses

AMAZON

About twice as many robots as it did two years ago, Amazon currently has 45,000 working in its warehouse. As you may recall, Amazon acquired the robotics company Kiva Systems in 2012, which greatly increased interest in warehouse automation. Employees would pack and stow supplies that Kiva was able to deliver straight to them. However, the corporation still employs more than 200,000 people, many of whom collaborate with Kiva, so don’t count on the robot takeover just soon.

TESLA

Adept Technology, Inc. created Tesla’s robots, which are categorized as autonomous indoor vehicles (AIVs). These self-navigating marvels stand out among the company’s robotic fleet because they can freely move around the facility, dodging humans and other barriers with the aid of sensors that can detect them.

DHL

Similar to Amazon, the logistics business DHL had to come up with workable techniques for choosing and packing its millions of packages. DHL administers DHL Supply Chain, which offers companies logistical solutions like transport, warehousing, and distribution in addition to being a significant provider of courier, package, and express mail services. In other words, implementing cutting-edge warehousing solutions not only for its own business but also for others helps DHL’s bottom line in numerous ways.

LEGO

We like to assume that the engineers who created the automated warehousing system for LEGO used the toys themselves to establish the groundwork for their trade. The Danish company that makes gigantic toys has long been at the forefront of innovation. Given that the enduring LEGO block has twice been crowned the “Toy of the Century,” it should not be surprising that the techniques used to create LEGOs are similarly cutting-edge.

Conclusion

With the continued growth of global ecommerce, smart warehouses are highly sought after. The necessity for effective and error-free fulfilment in warehouses has grown as the ecommerce sector has expanded. People that don’t modernize their warehouses with smart technologies will probably fall behind. Automation and artificial intelligence (AI) are the foundation of logistics in the future, making the burden more manageable and productive for human workers. Because of the ongoing changes in logistics, fully automated warehouses may be used considerably more frequently in the near future.

Author: Sachetanand