استكشاف إمكانات طباعة الأغذية ثلاثية الأبعاد: تغذية شخصية، تقليل النفايات، وطهي آلي

طباعة الأغذية ثلاثية الأبعاد هي عملية إنشاء الطعام باستخدام تقنيات تصنيع إضافية مختلفة. الأكثر شيوعًا هو محقنة من الدرجة الغذائية تحتوي على مادة الطباعة، والتي يتم تطبيقها طبقة تلو الأخرى من خلال فوهة من الدرجة الغذائية.

تأتي طابعة الأغذية ثلاثية الأبعاد الحديثة مع وصفات محملة مسبقًا، ويمكن للمستخدمين حتى تصميم الطعام عن بُعد باستخدام الكمبيوتر أو الهاتف أو جهاز إنترنت الأشياء الخاص بهم.

تاريخ طابعة الأغذية ثلاثية الأبعاد

كانت حركة الطباعة ثلاثية الأبعاد المتحمسة هي الأولى التي تدمج الطعام في الطباعة ثلاثية الأبعاد. قام فريق من قسم الهندسة الميكانيكية والفضاء بجامعة كورنيل بتطوير طابعة Fab@Home ثلاثية الأبعاد في عام 2006. هذه إحدى أولى الطابعات ثلاثية الأبعاد مفتوحة المصدر.

كانت طابعة Fab@Home ثلاثية الأبعاد جهازًا متعدد المواد يقوم بترسيب المواد باستخدام محاقن موقوتة بدقة. كانت قادرة على طباعة الجبن والشوكولاتة وعجينة البسكويت.

الوصول إلى نموذج التقرير (بما في ذلك الرسوم البيانية والمخططات والأشكال): https://univdatos.com/reports/3d-printing-market-3?popup=report-enquiry

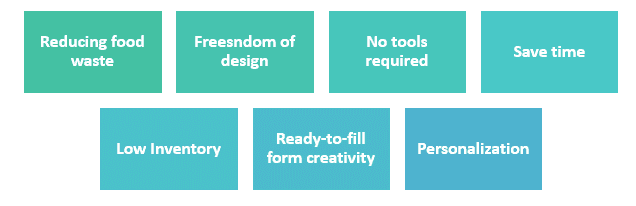

فوائد طباعة الأغذية

حدود طباعة الأغذية ثلاثية الأبعاد

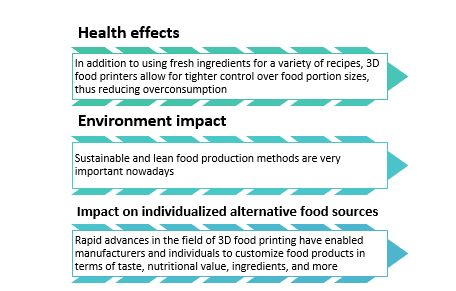

الطباعة ثلاثية الأبعاد - التأثير على صناعة الأغذية

بفضل شعبيتها المكتشفة حديثًا وقدرتها على إحداث ثورة في العديد من الصناعات، يتم الآن احتضان الطباعة ثلاثية الأبعاد على نطاق واسع في صناعة الأغذية. الأساس المنطقي وراء الأغذية المطبوعة ثلاثية الأبعاد هو الإمكانات الهائلة للطابعات ثلاثية الأبعاد المكتبية لطباعة وجبات لذيذة وبأسعار معقولة دون الحاجة إلى مهارات طهي واسعة.

في حين أنها لا تزال في مراحلها المبكرة، فإن الطباعة ثلاثية الأبعاد مهيأة لتغيير مستقبل صناعة الأغذية، وتأثيرها محسوس بالفعل على نطاق عالمي.

مستقبل طباعة الأغذية ثلاثية الأبعاد

تعزز تقنية جديدة تسمى طباعة الأغذية ثلاثية الأبعاد ابتكار المنتجات والإنتاج حسب الطلب والتخصيص. تمكن التكنولوجيا المستهلكين من تناول طعام طازج وصحي، وخلق تجارب تناول طعام جديدة، وتخصيص تفضيلات الطعام من حيث الشكل واللون والطعم والملمس والقيمة الغذائية. لكن التكنولوجيا لا تزال في المراحل الأولى من التطوير. تشمل أكبر التحديات إنتاجية العملية ومرونة الإنتاج وابتكار المنتجات والوظائف. حاليًا، لا يوجد سوى عدد قليل من مجموعات البحث النشطة التي تعمل على هذه التكنولوجيا.

من المتوقع أن يتم تحسين هذه التكنولوجيا الجديدة بشكل كبير خلال السنوات المقبلة من خلال فهم أفضل لخصائص المواد الغذائية وتأثيرات تقلب الأغذية على المنتجات النهائية مما يؤدي إلى التصميم التجاري وإنتاج منتجات غذائية جديدة مع زيادة سرعة الإنتاج والوظائف.

الخلاصة

توفر تكنولوجيا الطباعة ثلاثية الأبعاد في صناعة الأغذية إمكانيات جديدة للتغذية الشخصية والطهي الآلي وتقليل نفايات الطعام وغير ذلك الكثير. يمكن لتكنولوجيا الطباعة ثلاثية الأبعاد هذه في صناعة الأغذية أن تلبي الحاجة غير الملباة للتغذية الشخصية ونفايات الطعام والطلب على الغذاء وتوافره.

هذه تكنولوجيا متطورة مع العديد من المزايا، بما في ذلك توفير الوقت والكفاءة العالية والاستدامة وما إلى ذلك. يتجه مصنعو المواد الغذائية نحو التقنيات أو الأساليب التي تساعدهم على استخدام المكونات الغذائية بالطريقة الصحيحة لإنتاج أطعمة صحية ولذيذة وتقليل نفايات الطعام. يتزايد عدد سكان العالم بسرعة ويزيد الطلب على الغذاء وتؤدي نفاياته إلى ندرة مصادر الغذاء. يجب معالجة هذا الوضع بتقنيات جديدة مثل الطباعة ثلاثية الأبعاد، والتي يمكنها استخدام الموارد الغذائية بكفاءة مع القليل من النفايات أو بدونها.

المؤلف: ديپانشي سينغ

لمزيد من التفاصيل اتصل بـ:

UnivDatos Market Insights

C80B, Sector-8, Noida,

Uttar Pradesh 201301

للاستفسارات المتعلقة بالمبيعات، يرجى التواصل معنا على [email protected]